Technical data

| Designation |

RVK 500

VIS-Gas |

RVK 500

VIS-ÖL |

RVK 500

VIS-Öl Komp |

| Part no. |

83250 0200 |

83250 0400 |

83250 0000 |

| Boiler capacity |

500 l |

500 l |

500 l |

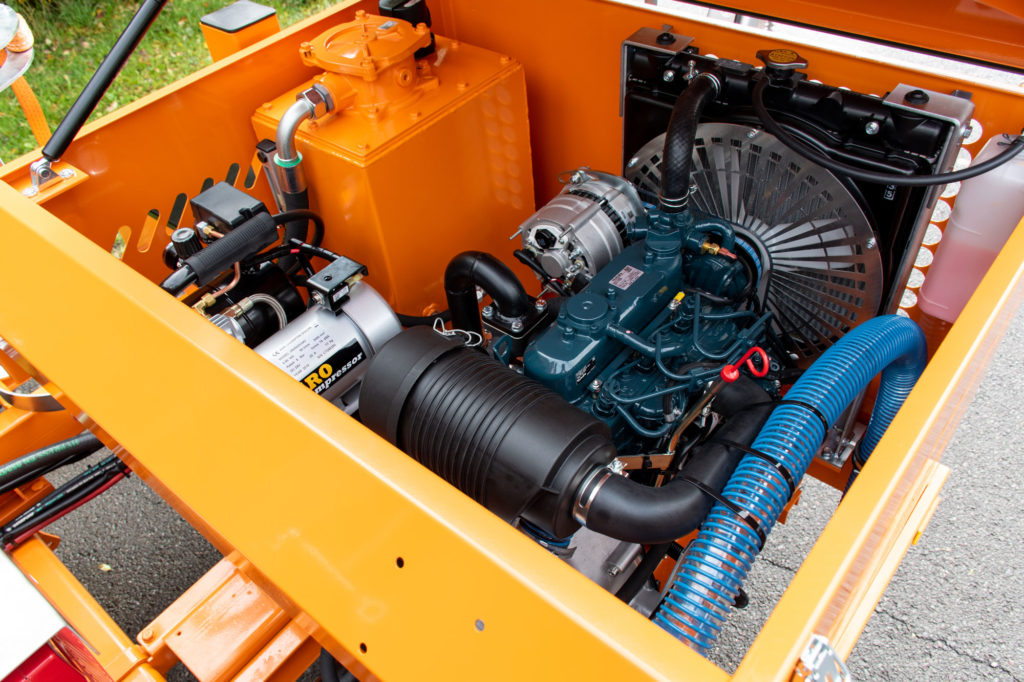

Drive engine

Type

Generator-

Power |

Kubota D1105

watercooled

18.5 kW at 3.000/min

24 V / 80 A |

Kubota D1105

watercooled

18.5 kW at 3.000/min

24 V / 80 A |

Kubota D1505

watercooled

26,2 kW at 3.000/min

24 V / 80 A |

| Length approx. |

5.100 mm |

5.100 mm |

5.100 mm |

| Width approx. |

1.850 mm |

1.850 mm |

1.850 mm |

| Height approx. |

2.250 mm |

2.250 mm |

2.250 mm |

| Approx. dead weight incl. operating fluids |

2.740 kg |

2.710 kg |

2.760 kg |

| Total loaded weight |

3.300 kg |

3.300 kg |

3.300 kg |

| Capacity diesel tank |

60 l |

60 l |

60 l |

| Capacity fuel oil tank |

Not applicable |

60 l |

60 l |

| Gas bottle holder |

2 Stück a 33 kg |

11 kg resp. 33 kg |

11 kg resp. 33 kg |

Compressor:

Approx. air output: |

90 l |

90 l |

1.300 l |

Propulsion:

Pressure tank: |

Electrically

40 l |

Electrically

40 l |

Hydraulically

40 l |

Drive propulsion:

Max speed

forward approx.

Max speed backward approx. |

3,5 km/h

2,0 km/h

|

3,5 km/h

2,0 km/h

|

3,5 km/h

2,0 km/h

|

Pumping capacity of the sealing pump approx.

Delivery / capacity approx. |

0 – 30 l/min |

0 – 30 l/min |

0 – 30 l/min |

Subject to technical changes!